Phone: +39 039 2847931

Phone: +39 039 2847931

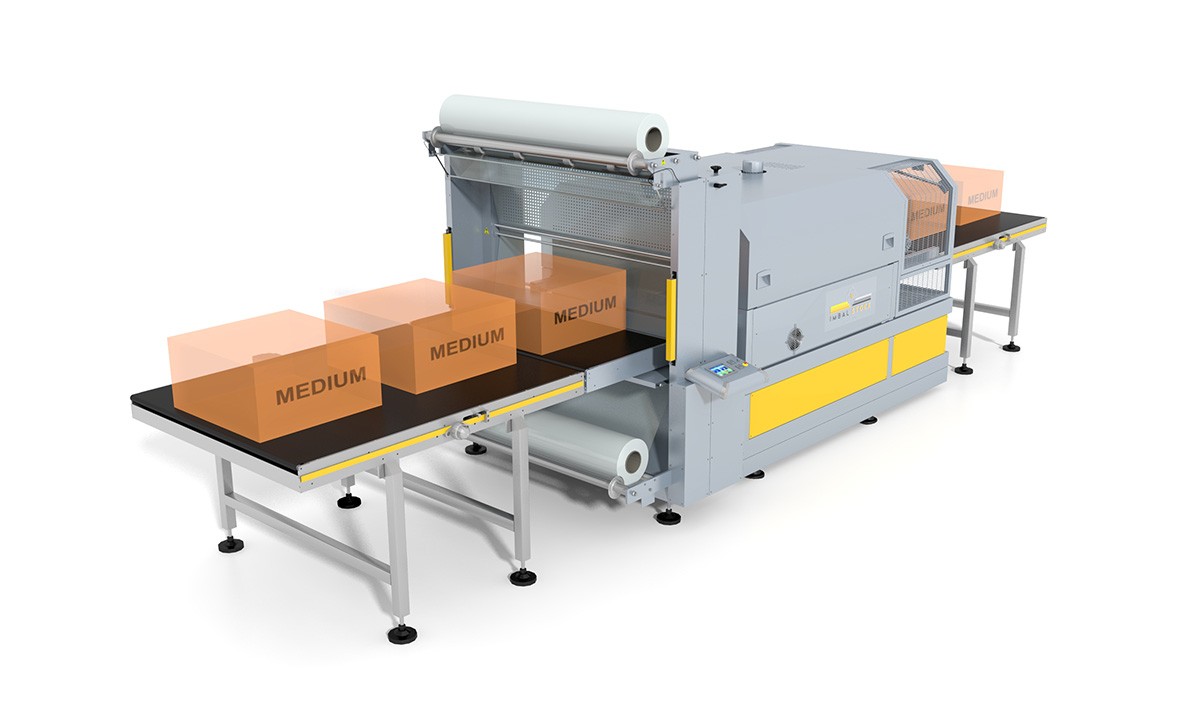

Choose one of our new models of IMBAL US bundling sleeve shrink wrap machine and you will obtain superior performance on film welding systems. These models present an innovative system for the welding of all kinds of film. Production from 10 to 25 pieces per minute. Filmmaker built in Italy.

Sealing bar: length 720 x H 360 mm pneumatically controlled by photocell

Power supply: 3 Ph + N + T 220/380 V 17 KW

Coil size: ø 250 x 680 mm

Pneumatic Supply: 6 Atm 12 n / liters x cycle

Tunnel spout: 680 x H 400 x 1300 mm length

Main features of the welder

Hot bar welding coated with Teflon controlled by an electronic thermoregulator.

Motorized upper and lower film unwinder with automatic film recovery, designed to facilitate the introduction of the products beyond the welding station.

Automatic in-line loading belt.

Horizontal photocell for product reading.

Sealing bar descent blocking safety if an obstacle is found on the trajectory of the sealing bar.

Films used: flat leaf polyethylene.

Average production: 120/600 pac / hour (purely indicative indication as they depend on the type of product, the size of the product and consequently on the package and the type of film used).

Main tunnel features

Galvanized steel wire mesh tunnel conveyor belt at a speed of 3.7 m / min (for the CAM 500 N model) and a speed of 5.2 m / min (for other models).

Air recirculation tunnel with temperature controlled by electronic thermoregulator.

Sheet metal shrink chamber designed for a positive transfer of heat from the heating elements (armored and finned) and for hot air recirculation in order to minimize heat losses.

Hot air flow with adjustable bulkheads.

Product cooling blower at tunnel exit.

- Inverter for speed regulation of the feeding conveyor belt.

- Loader and loading belts in various sizes.

- Double motorized film unwinder lower and upper for two separate reels.

- Rear film detachment system for sealing bar to optimize the detachment of the film from the sealing bar after welding

- Electric piece counter

- Inverter to control oven belt movement, with adjustment of movement speed

- Tunnel exit product compactors.

- Stainless steel conveyor belt, pulled by chains, with Ø 10/15 rubber coated rollers or with Teflon mesh coating.

- Unloading / loading roller conveyor or line in various sizes.

- Tunnel exit belt extension.

- Exceptional machine quality / price ratio

- Control panel, which offers the possibility of simple management of all machine functions.

- Machine with modular design. Sturdy frame built in a painted laminated steel tube.

- Height adjustable feet and wheels for location and transport.

- Access to all elements.

- Available painted and stainless.

- Protections and safety systems according to CE

Download the pdf relating to the machinery to have the essential data always there at hand.

THE BEST WAY TO SAVE WRAPPING FILMS

Our test center is at your service to allow you to try the right interaction between packaging machine and films, through specific tests on new materials, paper, PE, PP Cellophane films, PET films ready for recycling, bioplastics obtained from renewable fonts and compostable plastics (PLA polylactic acid).

If you are thinking of introducing a new biodegradable film, optimized for performance or ultra-thin, be sure to take advantage of our testing capabilities. We will find the best possible performance by avoiding actual downtime and costly production errors.